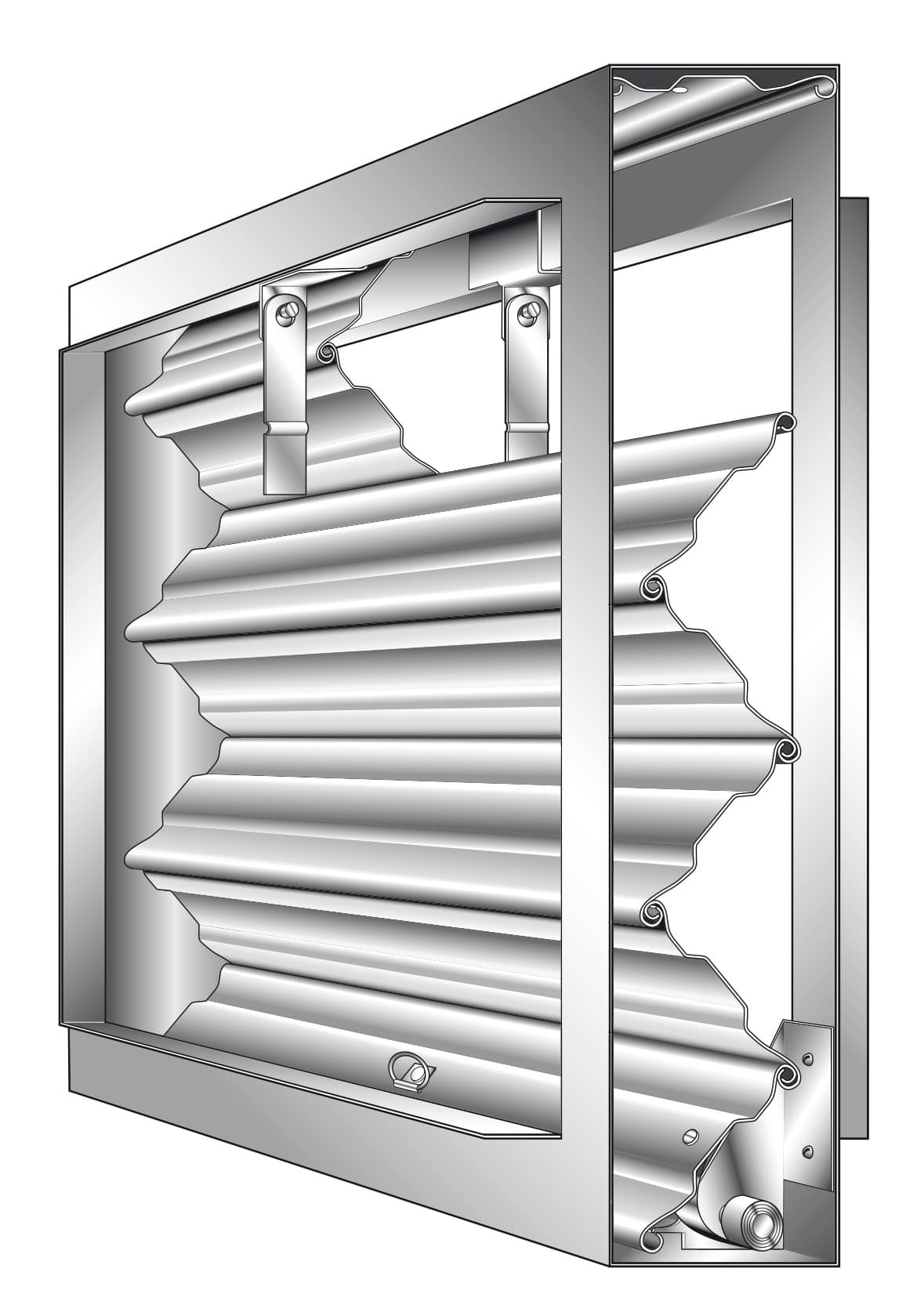

Curtain Blade Dampers have many features and options

(CE marked)

The product range has many features and options to meet the requirements of specifiers, contractors, local and national authorities. Fire dampers are available to suit both low/medium and high velocity applications.

Features and Benefits tested to EN 1366-2

- The majority of product variants are covered by third party Loss Prevention Certification Board (LPCB) product certification. This represents both full BS EN ISO 9001 quality compliance and a guarantee that the products are fully representative of those actually tested.

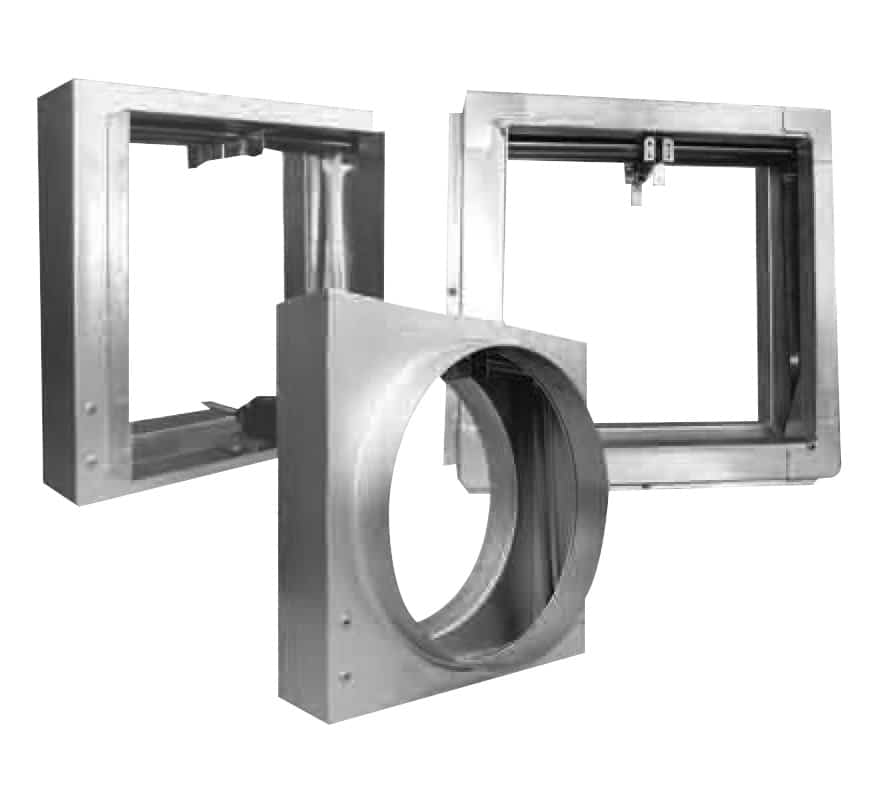

- Tested and certified installation variants of the damper are available to cover masonry walls, dry walls, batt walls and floors. These cover the majority of applications/supporting constructions that are required to maintain compartmentation.

- All tested installation methods give at least a E120 classification, usually only limited by the wall construction used.

- Sleeve and angle methods, HEVAC frame methods, cleat and drop rod methods and batt infill methods are available.

- Minimum size 100mm x 100mm.

- Maximum single section size 1200mm x 1000mm, available from the smallest size up to this in millimetre increments

- Multi-section configurations are available to specific customer requirements, but will be subject to BCA approval.

- Standard construction is a fully welded galvanised steel case, which gives a casing leakage that complies with Class C ductwork leakage specifications.

- Other combinations of galvanised mild steel, type 1.4016 (430) and 1.4401 (316) stainless steels for the blades and case are available to specific customer requirements.

- The damper has a strong and robust design to both meet the exacting fire testing requirements and be resilient to site handling. This is supported by sound production techniques which result in a quality product.

What is the ‘E’ classification?

To achieve the classifications to EN13501-3, fire dampers and fire and smoke dampers shall be tested to EN1366-2 and a 300Pa pressure difference is applied across the damper. During the fire test period, the integrity of the seal between the damper and the structure shall not have any gaps larger than 150mm x 6mm.There shall not be any sustained flaming. The largest size of damper to be manufactured for sale as a single section shall be fire tested.

E = Integrity

The maximum leakage permissible at 300Pa corrected to 20°C is 360m3/hr/m2 (100 l/s/m2) throughout the fire test period.

Fire dampers should be installed as tested.

Test reports showing testing to EN 1366-2 should be acceptable to meet the requirements of BS 476-20/22, but the reverse is definitely not the case and no classifications are available.

BS 476-20/22 and this is allowed worldwide in areas outside of the EU.

However, as a word of caution, in whichever case, the correct model must be selected, to match fire resistance time with installation method and with the supporting construction (wall or floor).

To ensure that all testing and assessments are traceable back to initial fire test reports, the FD series is product certificated by the Loss Prevention Certification Board (LPCB).This means that in addition to normal BS EN ISO 9001 compliance, the product is also checked to ensure that same product is being manufactured that has been tested or assessed.

We have a policy of continued testing and product certification to try and provide as broad a number of installation methods as possible.

We also follow regulation and standards development very carefully to provide input on changes and to be able to pass on relevant information to designers, specifiers, building control authorities (BCA’s) and installers.